Tire management system: Extending tire life and improving fleet performance

Fleet tires take on the heaviest burden—literally. Over time, uneven wear, missed rotations, and unnoticed damage can quietly drain resources and compromise safety. That’s why many fleet operators are now turning to tire management systems.

These systems do more than just log pressure or mileage. They provide complete visibility into tire usage, condition, and maintenance needs. From tracking installation dates to scheduling replacements, every tire gets monitored throughout its lifecycle.

The goal is simple: reduce avoidable costs, improve safety, and make tire data easier to manage across the fleet.

How a digital tire management system improves visibility

A digital tire management system gives fleet managers a complete view of every tire in use across companies, branches, and vehicles. From a single dashboard, users can access key data like:

- Tire brand, model, and serial number

Each tire has its own identity. This helps in tracking how long it has been used and where it was installed. - RFID tag and tire status

Tags (if available) allow faster scanning and real-time status tracking, whether in stock, in use, or retired. - Manufacture and purchase dates

These help estimate remaining life and support warranty tracking. - Tread depth and predicted distance

Logged manually or via sensors, these values guide when a tire should be rotated or replaced. - Price and cost tracking

Keeping purchase prices tied to tire performance helps measure return on investment. - Condition and pattern information

Condition notes and tread type give a clearer picture of whether the tire is safe to use or needs attention.

This level of detail helps teams make quick, informed decisions—whether it’s shifting tires across assets, identifying overused inventory, or planning bulk replacements based on wear data.

Benefits of using a tire management system

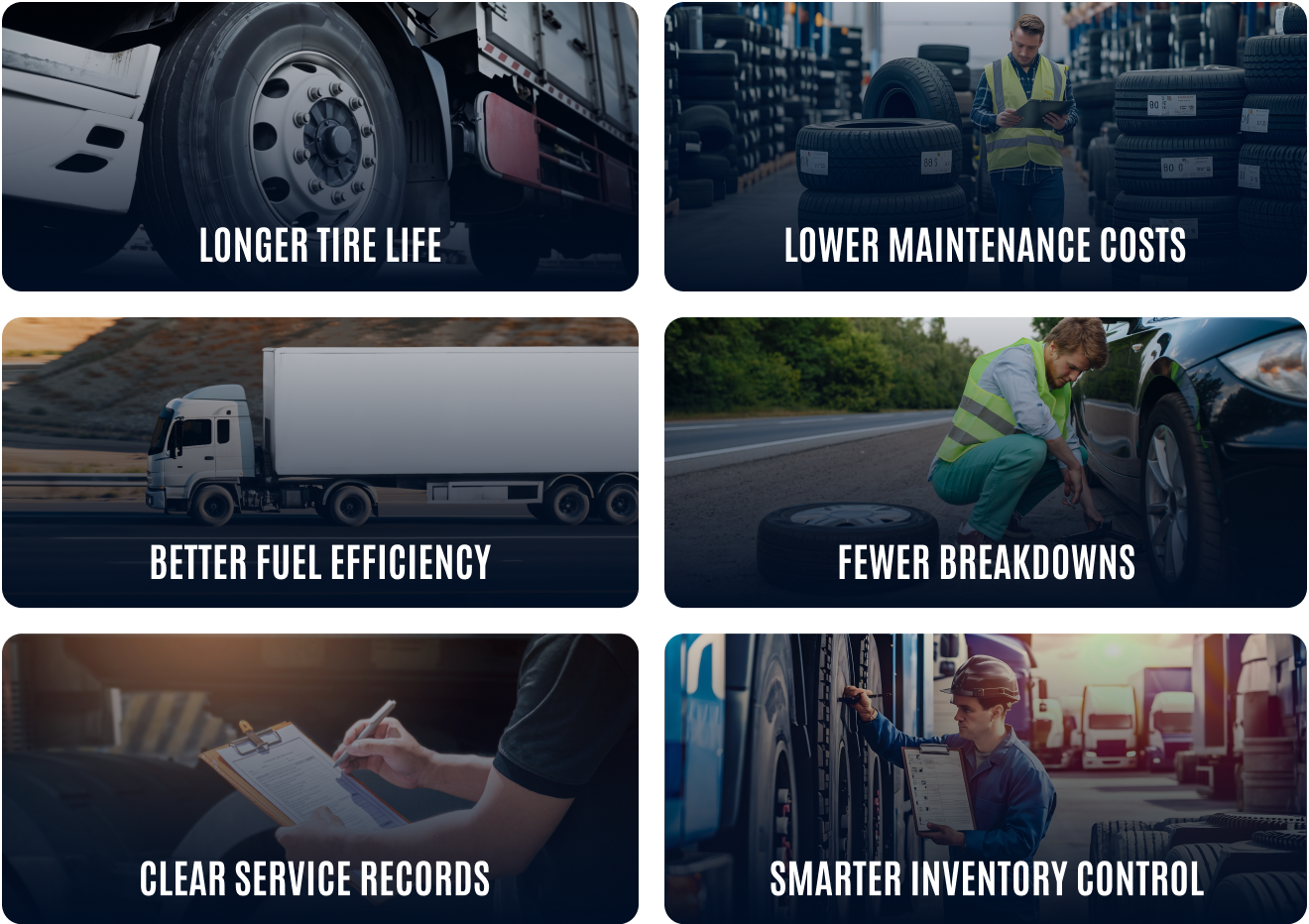

Managing tires with the help of a digital system brings many advantages. It saves time, reduces mistakes, and helps keep the fleet running smoothly. Here are some of the key benefits:

- Longer tire life

Regular checks and timely rotation help avoid uneven wear. This means each tire lasts longer before it needs to be replaced. - Lower maintenance costs

Knowing the exact condition of each tire helps reduce emergency repairs and improves service planning. - Better fuel efficiency

Healthy tires reduce rolling resistance. This helps vehicles use less fuel, especially on long routes. - Fewer breakdowns

When tires are regularly monitored, problems are spotted early. This helps avoid sudden failures on the road. - Clear service records

All tire details—like installation date, rotation history, and past issues—are stored in one place. This helps during audits or when planning replacements. - Smarter inventory control

The system shows which tires are in stock, in use, or removed. This avoids unnecessary purchases and keeps inventory organized.

By using a tire management system, fleet operators can take better care of one of their most important and costly assets.

Why it matters for system integrators and fleet businesses

A tire management system adds more than just maintenance value—it enhances business credibility.

- Fewer vehicle issues = better client satisfaction

- Organized tracking = faster service response

- Predictable tire health = stronger SLAs and long-term partnerships

For integrators, it’s a smart value-add that builds trust and supports scalable, efficient service models.

Final thoughts

Tires impact everything from safety to cost in fleet operations. Yet, without proper tracking, they’re often managed with guesswork. A tire management system changes that. It gives fleet operators full control over how tires are used, when they are serviced, and how much they are costing over time.

Whether managing a few vehicles or a large-scale operation, the system helps avoid waste, reduce risk, and improve planning. It’s a practical way to make fleet maintenance smarter and more predictable.