Cold chain fleets handle the transport of temperature-sensitive goods like dairy, frozen food, and pharmaceuticals. These vehicles must maintain strict environmental conditions across long routes, without compromise. But poor visibility, unplanned delays, and temperature fluctuations during transit often result in damaged consignments and revenue loss. Without proper monitoring systems, maintaining cold chain integrity becomes both difficult and costly.

Optimizing cold chain logistics with real-time monitoring

Introduction

Challenges

- Inconsistent temperature maintenance during transit: Different goods like dairy, seafood, or pharmaceuticals require strict temperature bands. Without automated temperature control and monitoring, even short deviations can damage product quality.

- Lack of real-time vehicle visibility: Fleet operators often don’t have live updates on vehicle location, delivery status, or performance. This leads to poor incident response and lack of control during emergencies.

- Unsecured cold storage compartments: Drivers or handlers may open container doors during transit, risking contamination, theft, or temperature rise. There’s no mechanism to monitor or prevent unauthorized access.

- Delayed deliveries due to route inefficiencies: Cold chain logistics is highly time-sensitive. Poor route planning, traffic delays, or improper job scheduling often result in missed delivery windows and product spoilage.

- Untracked tire wear in long-haul trips: Cold chain vehicles travel long distances continuously. Without proper tire tracking, unnoticed wear leads to breakdowns, delays, or increased fuel consumption.

Solution

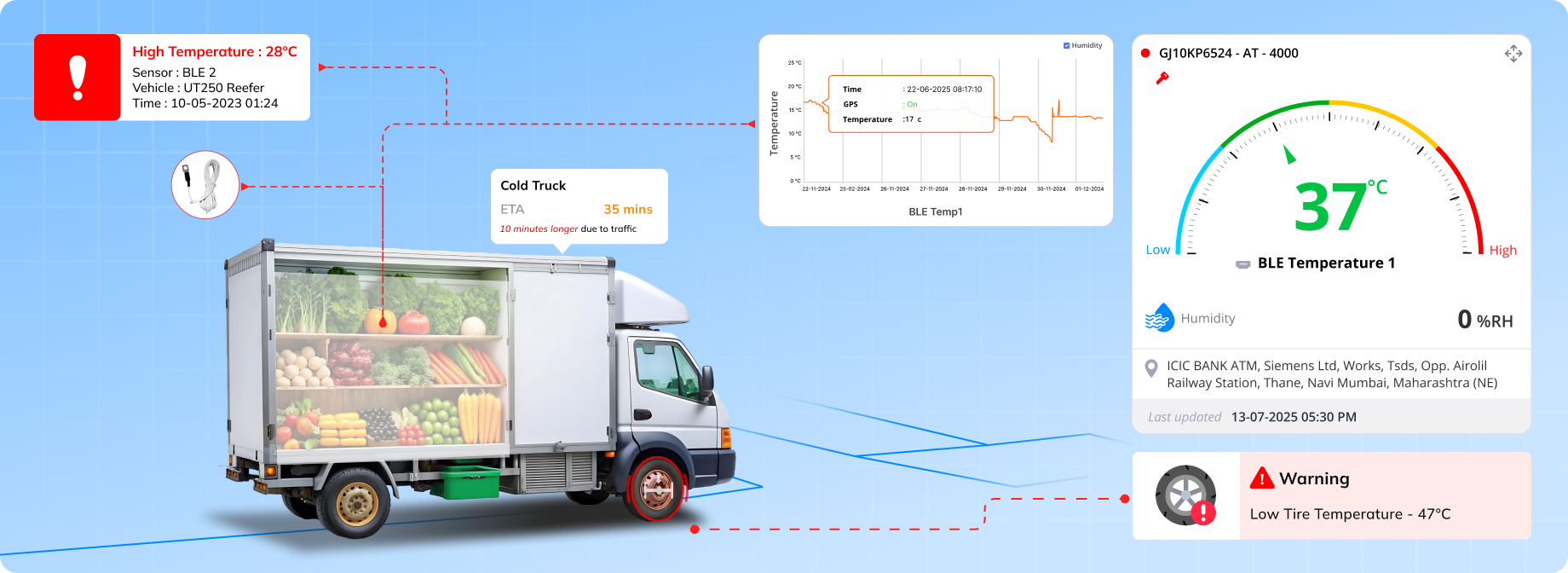

- Temperature monitoring dashboard and alerts: Each cold chain vehicle is equipped with temperature sensors linked to a central dashboard. Managers can track temperature data from multiple vehicles simultaneously and receive instant alerts if values move beyond the safe range, helping prevent spoilage and regulatory non-compliance.

- Real-time monitoring of vehicles: Fleet managers can monitor live vehicle movement, delivery progress, and reefer performance throughout the journey. This ensures better control over cold chain consistency and reduces the risk of unnoticed delays or equipment failures.

- eLock for door access and cargo protection: eLocks prevent unauthorized door openings during transit. The system logs every open/close event and enables remote locking if required, ensuring product safety and stable internal temperature throughout the delivery route.

- Route and job scheduling for better planning: Delivery routes and jobs can be planned considering the type of goods and required temperature conditions. This helps reduce delivery time, avoid temperature breaches, and ensure timely completion of cold chain jobs.

- Tire usage monitoring and replacement tracking: Track tire wear, mileage, and rotation cycles for each vehicle. This reduces the chances of sudden tire failure on long trips and ensures cold chain deliveries are not delayed due to preventable tire issues.

Results

- Improved Cold Chain Reliability: Real-time temperature monitoring helped maintain ideal conditions throughout transit, reducing spoilage by over 30%.

- Faster and Safer Deliveries: Optimized routes and tire health tracking minimized unplanned halts, cutting delivery delays by 25%.

- Stronger Compliance and Security: Digital logs from eLocks and temperature dashboards enabled audit-ready reporting and reduced unauthorized access incidents by 40%.