The Importance of Tire Pressure Monitoring Systems in California’s Unique Climate

Driving through California isn’t easy on truck tires. One minute you’re crossing a hot desert highway, and the next, you’re climbing steep mountain roads or dealing with cold coastal air. These quick changes in weather and elevation can mess with tire pressure in ways most people don’t think about. That’s why having a Tire Pressure Monitoring System in California is crucial for safe driving.

And here’s the issue even a small drop in tire pressure can hurt your fuel economy. The U.S. Department of Energy says that for every 1 PSI your tire is underinflated, you lose about 0.2% in fuel efficiency. When your fleet is running long distances every day, that adds up to a lot of wasted fuel and money.

On top of that, California has rules in place. The Air Resources Board (CARB) requires commercial vehicles to keep their tires properly inflated not just for safety, but also to help reduce emissions.

So, installing a Tire Pressure Monitoring System (TPMS) isn’t just a good idea anymore. For trucking fleets in California , it’s becoming a must for safety, for savings, and for staying compliant.

Why Tire Monitoring System Is a Bigger Deal in California

You may think tire pressure is a minor thing but here in California, it’s not.

Let’s break it down:

- Coastal chill in the Bay Area one hour, desert heat in Barstow the next.

- Long, steep climbs up Grapevine Pass or Sierra Nevada ranges that test every part of your vehicle especially tires.

- Wild shifts in altitude, humidity, and temperature across a single route.

Now add to that:

- Tight delivery windows

- High cargo value

- Stricter environmental rules

It’s not just a climate issue. It’s a business issue.

What Is a Tire Pressure Monitoring System And Why Does It Matter?

In simple words, a Tire Monitoring System keeps an eye on your tire pressure automatically.

It sends live alerts to the driver if a tire is over- or under-inflated. Some systems also show temperature readings, so drivers can spot problems before they become emergencies.

There are two types:

- Direct TPMS: Accurate sensors placed directly on each tire.

- Indirect TPMS: Uses ABS data to guess pressure (less accurate, more basic).

For heavy-duty trucks navigating California’s wild terrain, direct TPMS is the way to go.

The Real Impact: What TPMS Brings to the Table

Let’s get practical. Here’s what TPMS really does for fleet owners and drivers:

1. Fewer Blowouts. Safer Roads.

And most tire-related accidents come from low pressure that wasn’t caught in time. With TPMS, your drivers don’t have to guess. They get real-time warnings. That means fewer crashes, fewer roadside emergencies, and more peace of mind.

2. Save Fuel, Save Money

A drop of just 1 PSI in tire pressure can lower fuel efficiency by 0.3%. Multiply that by hundreds of trucks and thousands of miles and you’re losing money every single day.

TPMS helps fleets save up to $2,400 per truck each year in fuel and maintenance. And when margins are tight, that’s a big deal.

3. Protect Your Tires

Properly inflated tires last longer sometimes up to 20% longer. That means fewer replacements, less downtime, and more control over your operating costs.

4. Stay Compliant with California Rules

California has its own set of air quality and vehicle regulations. One of them is the CARB tire inflation regulation, which requires fleets to maintain proper tire pressure.

TPMS makes compliance easy. No paperwork. No manual checks. Just proof that you’re running a clean, efficient fleet.

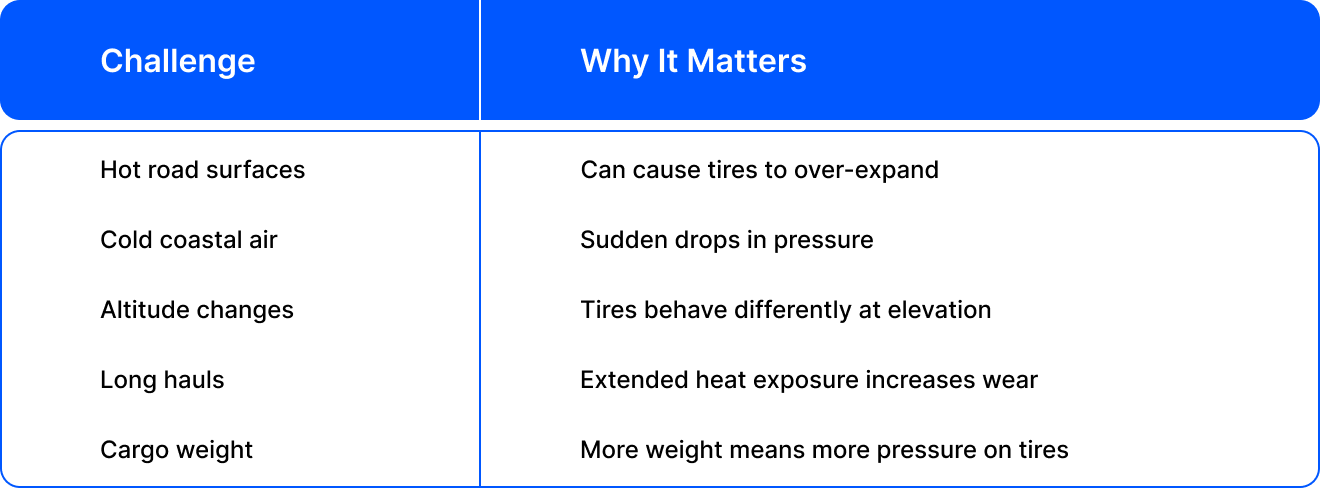

What Makes California So Tough on Tires?

You already know the weather shifts are intense. But there’s more:

Without a reliable way to track PSI and temperature, it’s like driving blind.

A Friendly Checklist: What to Look for in a Tire Monitoring System

If you’re thinking about installing a system, here’s what matters most:

- Real-time alerts

- Easy-to-read dashboard

- Works in heat, rain, and dust

- Long-lasting sensors

- Fleet-wide tracking dashboard

- Integration with your GPS/tracking software

And if your trucks are running EVs or hybrid engines? TPMS helps those too. They rely even more on tire health for energy efficiency.

Common Questions from Fleet Managers

Q: Is TPMS hard to install?

A: Not at all. Most systems are plug-and-play. Others can be fitted during routine maintenance.

Q: Will it work across all my routes?

A: Yes. Good TPMS systems are designed for long hauls, rough roads, and all climates including California’s extreme ones.

Q: What about sensor damage?

A: High-quality TPMS systems are waterproof, heat-resistant, and built to last.

How to Start: A Simple Plan

- Start small: Choose 5–10 trucks from different routes.

- Track the results: Look at fuel use, tire issues, and downtime.

- Train your team: Drivers should know how to respond to alerts.

- Roll it out: Once you see the ROI, expand across your fleet.

- Stay on top of it: Set reminders for battery checks and updates.

You don’t need to overhaul everything in one day. A smart rollout plan gets you all the benefits without disrupting operations.

A Quick Story to End On

One of our partner fleets shared this recently.

Their driver was hauling tech equipment up to Sacramento. It was hot over 100°F. Midway through the trip, the TPMS showed one tire heating up fast. It wasn’t flat yet, but it was headed there. Fortunately, he pulled over, got it checked, and found a slow leak. If he had driven 30 more miles, it would’ve blown. Instead, he made it on time. No damage, delay and loss.

That’s the difference TPMS makes.

Final Thoughts

Tires are easy to overlook but they’re doing the heavy lifting every mile. In a state like California, with all its weather, traffic, and terrain challenges, TPMS isn’t optional anymore.

It’s a smart move. It’s a safety move. And it’s a cost-saving move.