Logistics fleets include trucks, trailers, vans, and containers that move goods across cities, states, and borders. These vehicles run around the clock, handling tight delivery schedules and varying cargo loads. But without real-time tracking, route planning, or driver insights, it becomes hard to ensure on-time delivery, fuel efficiency, and vehicle reliability. This slows down operations and affects service quality across the supply chain.

Ensuring Fleet Efficiency in the Logistics and Transport Sector

Introduction

Challenges

- No real-time delivery visibility: Logistics vehicles move across vast routes with strict delivery schedules. But without live updates, managers can’t track where a vehicle is or whether it’s delayed. This affects planning and reduces coordination between dispatch teams and clients.

- Driver misuse and untracked behaviour: Drivers may take unauthorized breaks during long trips. Without live monitoring or route history, it’s difficult to verify activity. This causes delivery delays and increases operational risks.

- Fuel theft and inconsistent usage: Fuel is often filled at remote locations with no verification system. Without sensors or usage logs, teams can’t confirm how much was added or if it was used properly. This leads to frequent fuel loss and uncontrolled expenses.

- Manual route planning and poor trip execution: Routes are usually decided based on driver knowledge or manual input. There’s no tool to optimize delivery paths or avoid delays. This results in longer trips, wasted fuel, and missed delivery slots.

- Missed maintenance and roadside breakdowns: Vehicles cover long distances without a clear maintenance schedule. Without reminders or engine-hour tracking, services are skipped. This leads to sudden breakdowns during trips and delays in cargo delivery.

- Consignment tampering and security issues: Cargo vehicles often carry high-value or sensitive goods across long routes. Without proper locks or monitoring, there’s a risk of unauthorized access during transit. This leads to theft, disputes, and damaged customer trust.

Solution

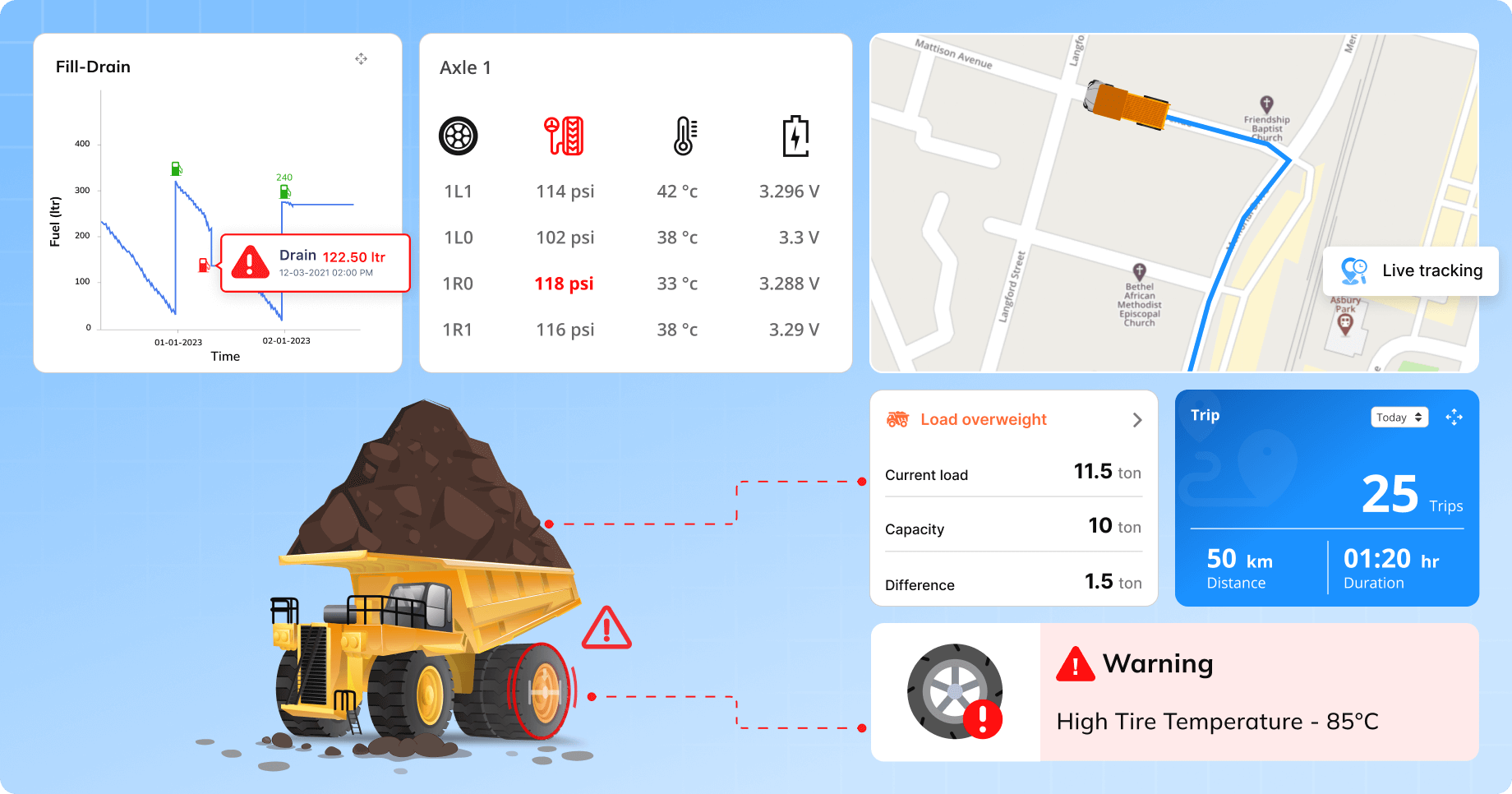

- Live tracking with delivery status updates: Track every logistics vehicle in real time across highways, cities, or remote regions. View current location, delivery progress, and estimated arrival time. Get notified instantly if a vehicle is delayed or goes off route.

- Driver behavior monitoring tools: Track driver activity throughout the trip with complete visibility. Get alerts for long halts, route changes, or overspeeding. Identify risky patterns like harsh braking or quick acceleration to improve safety and driving standards.

- Fuel tracking to prevent misuse: Keep a close watch on every fuel fill and usage pattern. Get alerts for sudden drops or irregular consumption. This helps prevent fuel theft, avoid hidden losses, and stay within budget.

- Route and job planning tools: Plan the best delivery routes based on location, traffic, and delivery time. Assign the right job to the right vehicle without delays. This improves trip efficiency, reduces confusion, and helps complete deliveries on time.

- Maintenance alerts based on usage: Set service reminders based on mileage or engine hours. Get notified before a breakdown happens. Ensure timely maintenance to keep vehicles road-ready and reduce repair costs.

- E-lock support for consignment security: Use electronic locks that can be remotely managed and tracked. Allow only approved unlocks at verified delivery points. Get alerts for forced entry or route deviations, ensuring goods remain secure until delivery.

Results

- Better control over delivery timelines: Live tracking and timely updates helped teams manage delays and reroute vehicles when needed. This improved delivery accuracy and reduced missed deadlines.

- Improved driver performance and road safety: Tracking behavior during trips reduced risky driving. This helped drivers follow routes better and maintain safety on long hauls.

- Reduced fuel misuse and lower operating costs: Monitoring fuel usage patterns prevented theft and unnecessary fills. This brought better fuel control and noticeable cost savings.