Tanker fleets in the oil and gas industry face critical challenges during fuel transportation. Delays, theft, and unauthorized access can result in major financial and safety risks. Even a single incident can lead to fuel loss, delivery failure, or contract penalties, directly affecting business profits. Basic location tracking is no longer enough to manage these operations. Businesses now rely on advanced tanker tracking software to monitor vehicle movement, control fuel access, and improve delivery efficiency through real-time data.

Improving security and efficiency in oil and gas fleets with tanker tracking

Introduction

Challenges

- Fuel theft during trips: Tankers often stop in isolated or unauthorized areas during transit. Drivers or external parties may open compartments and remove fuel without approval. These thefts are hard to detect without proper monitoring tools. Over time, this leads to frequent product losses, reduced delivery volumes, and a lack of trust from clients receiving short-filled deliveries.

- No live view of vehicle location: Without real-time tracking, fleet managers cannot check where a tanker is at any given moment. If a vehicle is delayed, takes a longer route, or stops unexpectedly, there is no instant way to respond. This affects delivery schedules and raises safety concerns in high-risk or remote areas.

- Manual job planning slows operations: Many fleets still use manual methods to assign delivery tasks and plan routes. This increases the chances of miscommunication, inefficient routing, and underused vehicles. Delivery delays and route overlaps become common, especially in fast-paced operations handling multiple tankers per day.

- Unsafe driving goes unchecked: Transporting fuel or gas requires careful driving. But risky behavior like harsh braking, over-speeding, or sharp turns can go unnoticed. Without visibility into how each vehicle is driven, companies face higher chances of accidents, cargo damage, and increased liability.

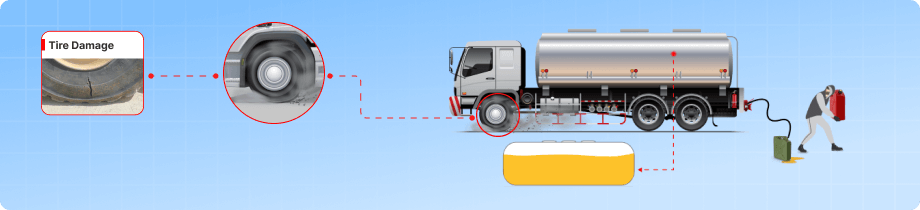

- Missed maintenance and tire issues: Tankers cover long distances and require regular servicing. Without automated reminders or health checks, important tasks like oil changes, brake inspections, or tire rotations are missed. Low tire pressure, if not monitored, can cause blowouts or unsafe handling, especially when carrying flammable goods. These failures can lead to on-road breakdowns and delivery interruptions.

Solution

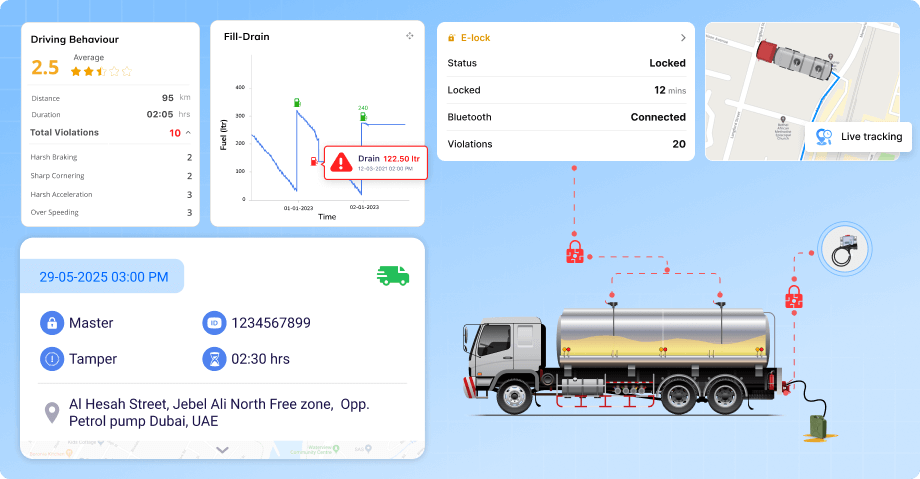

- Control tanker access with e-locks: Install electronic locks on each tanker compartment. These locks can be controlled remotely and only open within approved delivery zones using software. If someone tries to open them in an unauthorized area, alerts are triggered instantly. This ensures fuel is only accessed at the right place and time, reducing theft risks.

- Track vehicle location in real time: Use GPS tracking to monitor the exact position of every tanker. Fleet managers can view the live location, trip progress, and route taken. If a vehicle goes off-route or faces unexpected delays, they are notified immediately. This improves delivery planning and increases overall control.

- Assign jobs and route optimisation: Plan delivery routes and assign jobs using the software. It considers driver availability, vehicle assignment, and delivery location. Managers can avoid route overlaps, assign tasks faster, and ensure tankers are used efficiently. This saves time and helps complete more deliveries each day.

- Monitor driver behavior on every trip: Track events like speeding, harsh braking, and sharp turns in real time. The software records each driver’s performance and highlights risky driving patterns. This helps in coaching drivers, reducing accident chances, and protecting high-value cargo during transit.

- Schedule maintenance with timely alerts: Set up reminders for vehicle servicing, brake checks, and other maintenance tasks. The system alerts managers before issues occur, avoiding last-minute breakdowns. Tire pressure monitoring also ensures that tankers run safely, preventing blowouts and extending tire life.

Results

- Fuel theft incidents reduced by up to 30%: With the use of e-locks and fuel sensors, tanker compartments stayed secure throughout the trip. This helped companies reduce fuel losses and improve delivery transparency with clients.

- On-time deliveries improved by 25%: Live tracking and route planning made it easier to manage jobs and avoid unnecessary delays. As a result, fleets were able to meet delivery schedules more consistently and handle more trips within the same workday.

- Vehicle downtime decreased by 40%: Automated maintenance reminders and tire pressure monitoring led to fewer breakdowns. This not only improved road safety but also helped maintain better service continuity across the fleet.