Manufacturing plants are complex spaces with constant movement of workers, tools, and materials. Keeping track of everything in real-time is critical for safety, efficiency, and productivity. Indoor tracking software helps plant managers monitor operations inside the facility and make faster, data-driven decisions. For system integrators and resellers, it’s a strong solution to offer in industrial settings that need better control and visibility.

Indoor Tracking for Manufacturing Plants

Introduction

Challenges Faced by Manufacturing Plants

- Tool and equipment misplacement: Tools and machines are often moved between workstations. When items are misplaced or lost, it delays production and increases costs.

- Low visibility of worker movement: Managers don’t always know where workers are during critical processes. This makes it hard to ensure proper staffing and safety.

- Inefficient workflow monitoring: Without live tracking, it’s difficult to understand how materials flow across departments. Delays and bottlenecks go unnoticed until it’s too late.

- Workplace safety risks: In large factories, detecting workers in restricted or hazardous zones is difficult. This puts workers at risk and violates safety protocols.

- Manual log tracking: Tracking asset or worker location manually is time-consuming and prone to error. It wastes time and gives outdated insights.

Solution with Indoor Tracking Software

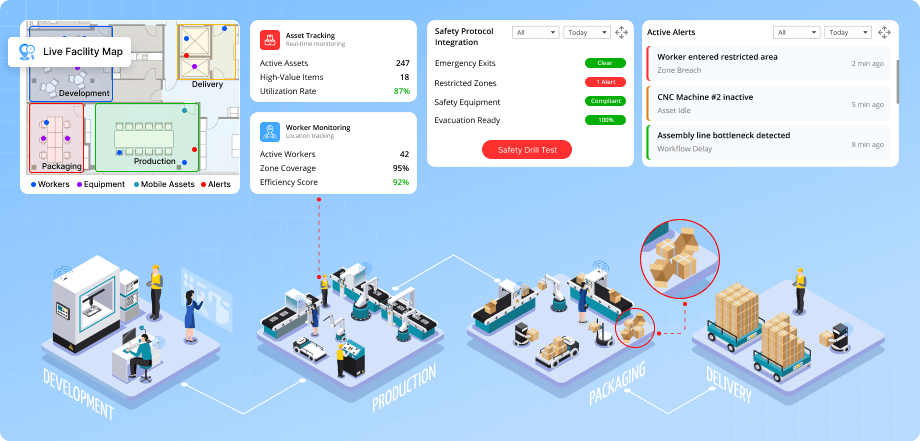

Indoor tracking software uses BLE beacons, Wi-Fi, and sensors to track assets and people inside a manufacturing plant in real-time. It creates a virtual map of the facility and provides insights that help improve operations and safety. Key features include:

- Real-time asset tracking: Monitor the location of tools, equipment, and machinery. Easily locate high-value or frequently used items.

- Worker location monitoring: Track worker movement across zones. Ensure staff is deployed in the right places at the right time.

- Workflow visibility: Monitor material and task flow across departments. Spot inefficiencies or delays quickly and take action.

- Zone-based alerts: Get notified if workers enter restricted or hazardous zones. Improve safety and compliance with automated alerts.

- Historical tracking logs: View past movement data of assets and employees. Use this for audits, reporting, or optimization planning.

- Integration with safety protocols: Combine tracking data with safety systems. Trigger alerts during emergencies or safety breaches.

Results Achieved

- Reduced equipment loss: Managers could locate tools instantly. This saved time and avoided unnecessary replacements.

- Better workforce allocation: Worker movement data helped assign tasks more efficiently. The right people were in the right place at the right time.

- Improved production flow: Real-time monitoring of materials and tasks helped identify bottlenecks. Teams could respond faster and keep production on track.

- Higher workplace safety: Entry alerts for restricted areas improved compliance and reduced accidents. Workers stayed safer, and protocols were followed.

- Less manual work: Tracking was automated, removing the need for manual log entries. This reduced human error and gave live, accurate data to decision-makers.